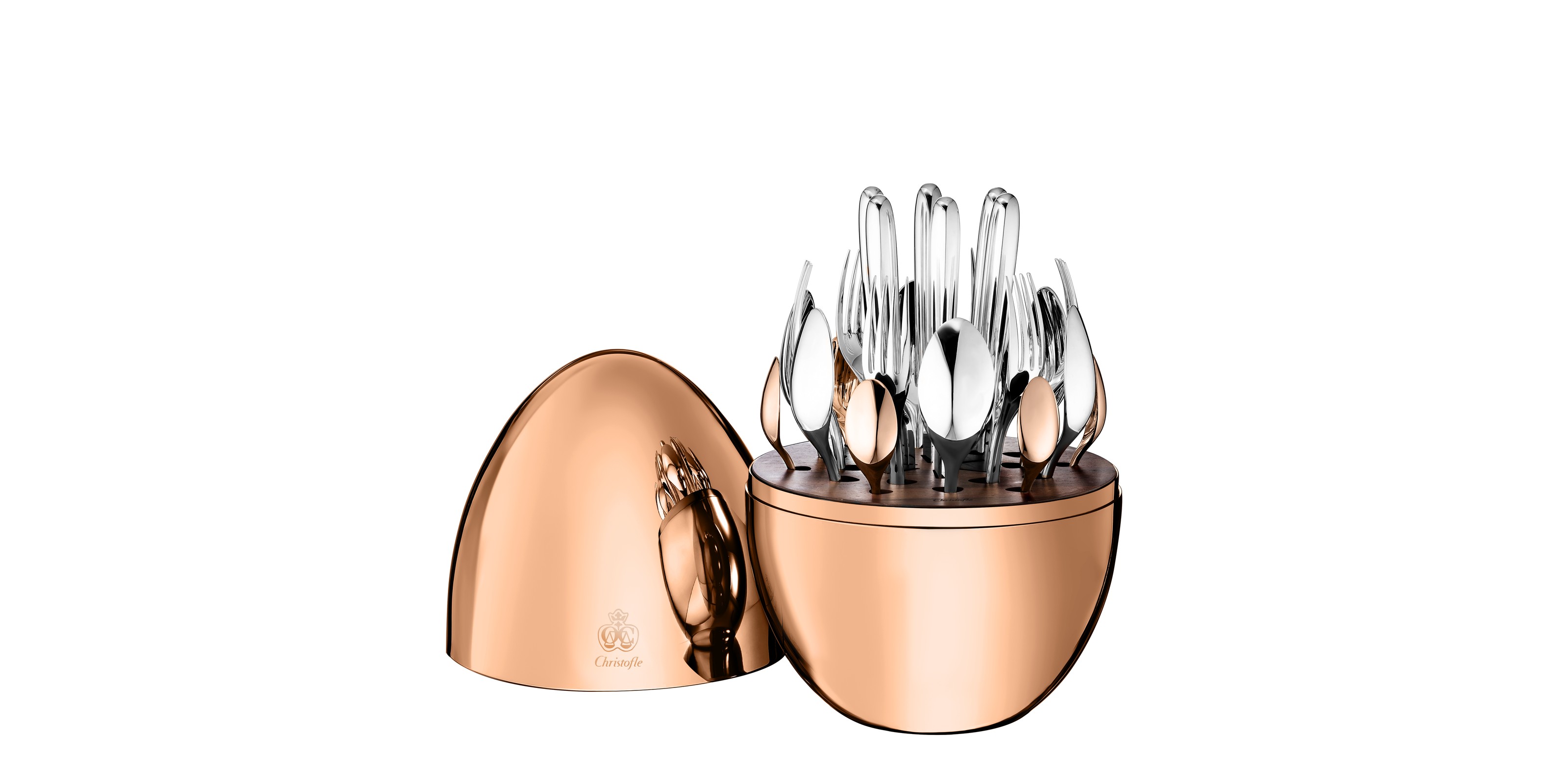

10 beautiful pieces of tableware to accompany your modern table

21st April 2017

Express yourself with a contemporary coffee table

10th May 2017Dekton Tables: the ultimate high-tech tables

You need a table made tough for family life, you need a unique Mac+Wood Dekton table.

The revolutionary product Dekton launched in 2013. This completely inorganic substance is made from complex raw materials, used in glass, porcelain and quartz surface production. Before its launch the company that created it, Cosentino, invested $172 million into the new product, including 22,000 hours of research and development and the construction of a new state-of-the-art factory in Spain.

Dekton is a material with unique characteristics and seemingly endless applications from tables, countertops, flooring, siding, facades for both inside and outdoors.

Dekton is made in a process that combines technologies from three different industries; glass, porcelain and quartz. This process lead to the development of a new production method called Particle Sintering Technology.

This process is like an accelerated version of the natural metamorphism that rocks and stone undergo when subjected to heat and pressure over thousands of years. To manufacture Dekton, Cosentino has reduced this process to four hours with extreme heat and pressure resulting in an entirely new ultra compact material. The press used in the ultra-compaction can bring 25,000 tons of pressure to bear.

All of this highly scientific process has lead to a product with unique properties, which can best be taken advantage of in the form of a Dekton table.

The properties of a Dekton table that make it so useful fall into four categories.

Firstly, the table is non-porous and this means it is highly stain resistant. Hosting a party with a Dekton table? All those glass rings which could ruin another surface can be wiped away easily with no lasting marks, even the morning after.

In a video demonstration of the stain resistance of Dekton tables, they spray the table with a large X in red paint, dry it with a hair dryer and then remove it with little more than a cloth and water.

Secondly, the tables are highly UV resistant. Normally surfaces are affected by UV light and the colours become washed out and faded. However, a Dekton table will hold its colour permanently due to its UV resistance. This means the beautiful colour you spent time choosing from the myriad of options will really last.

Thirdly, Dekton tables are pretty indestructible. The enormous pressures Dekton tables are exposed to during production means that they can resist any scratch, abrasion, or mechanical attack. This makes them perfect for hard use and preparing food on, without fear of chips or scratches. In another demonstration of the Dekton table’s surface, the table is attacked with a screw driver and rather than scratch or chip the tool is repelled showing a few sparks in slow motion!

Finally, Dekton tables, like a good chef, can stand the heat. Dekton tables are completely noncombustible. They can be blowtorched and abused by pots and pans and never show a mark. Forget using pot stands or trivets, you can place anything hot on a Dekton table without worry. Dekton tables also resist temperature at the other end of the scale and are resistant to ice and thawing.

Dekton tables come in a wonderful array of carefully created colours and patterns. These colours make the surface of a Dekton table suited to any room and style. At MAC+WOOD we finish the job by creating the perfect bespoke frame to pair with the surface and style. We make these frames in any colour or in brushed steel and in any one of our beautiful designs.